The Tiny Type Museum & Time Capsule

The museum edition is sold out as of 17 Feb. 2022. This page provides archival information.

You can still order the book Six Centuries of Type & Printing as a separate item:

Letterpress edition (includes ebook, ships immediately)

Ebook edition (available immediately)

A numbered and signed letterpress-printed posted by Stephanie Carpenter commissioned in an edit of 115 for the museum is available in very limited quantities. Follow this link to purchase.

Each drawer of the tiny type museum & time capsule has its own unique treasures.

The Tiny Type Museum & Time Capsule is a celebration by journalist and printing historian Glenn Fleishman of type and printing, and an effort at preserving history for future generations to re-discover. Each custom, handmade wood museum case holds several dozen genuine artifacts from the past and present, including a paper mold for casting newspaper ads in metal, individual pieces of wood and metal type, a phototype “font,” and a Linotype “slug” (set with a custom message), along with original commissioned art, a letterpress-printed book, and a few replicas of items found in printing shops.

The museum includes a letterpress-printed book written for the project, Six Centuries of Type & Printing, in which Fleishman traces the development of type and printing starting before Gutenberg printed his Bible around 1450 up through the present day. This book acts as “docent” for the museum, providing insight into the stages in technological and artistic development that took place, and explaining the importance and nature of the artifacts. It also slides out neatly as part of a sled from the top of the museum case, and provides the visible name.

Each museum also includes a curator’s guide that details each specific or category of artifact—and a secret compartment.

The project started with a crowdfunding campaign that completed 1 March 2019 and in which 56 museums were sold from a total edition for sale of 104. The remainder were sold between March 2019 and February 2022. (The full edition is 108; 4 were hors de commerce.). The edition is now sold out.

Read about the development of the Tiny Type Blog and receive new posts to the blog via email. You can view photos of artifacts via this Flickr gallery. You can also subscribe to Glenn’s very low-volume project announcements list for future updates about this and other projects.

For more about type, book, and printing history, listen to the Tiny Typecast podcast series, which you can subscribe to via this RSS link, in Apple Podcasts, or in your favorite podcast app. In the series, Glenn speaks with people about how type and printing’s past keeps informing designers, printers, and others in the present, and about the historic and modern making of books, including interior elements like an index.

The bottom drawer of a Tiny Type Museum & Time Capsule, showing a typical selection of artifacts

What’s in Each museum

The Museum & Time Capsule

Each custom, handmade wood museum case holds a few dozen genuine printing and typographic artifacts from the past and present, including a paper mold for casting newspaper ads in metal, individual pieces of wood and metal type, part of a phototype “font,” and a Linotype “slug”* (set with a custom message), along with a special piece of letterpress art commissioned for the project, a letterpress-printed book, and a few practical items once found in every printing shop.

Ingredients for the museum have been sourced from active letterpress printers, type foundries, artists, and nooks and crannies where people stashed the past in the hopes of someone showing interest in preserving it. I pulled all of this together into a unique collection that’s impossible to find outside of a full-scale printing history museum and put it into your hands.

The museum comes with a letterpress-printed book, Six Centuries of Type & Printing, in which I trace the development of type and printing since Gutenberg printed his Bible around 1450. This book is the “docent” for the museum, providing insight into the stages in technological and artistic development that took place, and explaining the importance and nature of the artifacts. It slips neatly onto a sled fit into the top of the museum case, with the name of the museum stamped in gold-tinted letters.

The museum—measuring 11×7×5 inches (28×18×13 cm)—lays out the history of printing in miniature, and serves as an object of study and conversation, a teaching tool, and a time machine—offering a small, but deep, glimpse into the past to those who discover it in years to come.

Glenn explains the museum’s contents and discusses centuries of type history in this talk presented in June 2019 in San Francisco.

What’s Included in Each Museum

Each museum contains the same general set of objects, though the complete set is unique from museum to museum. Only a few elements were mass produced in the past or present. Items in each museum include:

The book, Six Centuries of Type & Printing (see below)

Cast pieces of metal foundry type

A small metal plate used as an image in newspaper printing

A metal “ad cut” used for generic newspaper and other ads

A historic piece of wood type

A piece of wood type made fresh in 2019 at the Hamilton Wood Type & Printing Museum

A modern laser-cut piece of wood type produced in 2019

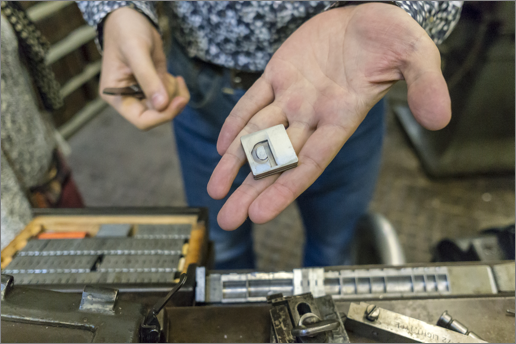

A matrix (mold) from Linotype and Ludlow systems for casting slugs of type for newspapers

Matrices for Monotype casting equipment, including composition matrices used to typeset books and for other purposes, and Electro Display and Super Caster matrices for larger sizes of type

A type “slug,” or “line o’ type,” with custom text that you choose as part of your reward cast on a Linotype†

A historic slug created for an advertisement or newspaper

A section of flong, a paper mould used to make metal plates for relief printing, also known as a “mat,” short for “matrix,” and used heavily in the distribution of advertising and clip art

A sheet or section of a phototype font

A machinist’s punch to demonstrate the nature and appearance of a type punch

A piece of photopolymer plate, a modern letterpress digital/analog hybrid product

Samples of printed letterpress (traditional and “digital”) and offset

A scale-model replica of a California Job Case, a standard drawer of metal type for typesetters

A type gauge, a ruler used for measuring type and other printing aspects, including notches that correspond to sizes of metal type

A piece of leading (vertical spacing) and furniture (wooden separators) used in letterpress typesetting

A commissioned work from artist and printer Stephanie Carpenter that incorporates old and new

A USB memory stick with public domain and licensed resources relating to the history of type and printing.

A version of the Doves Type, Robert Green’s revival of the legendary Doves Press typeface. The museum includes a digital font with the original character set as used by the press. It also includes a coupon and discount for the typeface as expanded by Robert.

Each museum also includes digital copies of four modern movies about printing and type:

Graphic Means, directed by Briar Levit, covering the technological and societal transition from the metal era to the digital one

Linotype: The Film, directed by Doug Wilson, tracing the history of the Linotype, including remarkable interviews with some of the last living career Linotype operators

Making Faces, directed by Rich Kegler of P22 Type Foundry, about the life and work of metal type cutter and designer Jim Rimmer

Pressing On, directed by Erin Beckloff, looking at a last generation of letterpress printers and type casters, and how they are handing off the mantle to younger people

The cover of the curator’s guide

Museums include an illustrated guide for curators that explains type of artifact found in the set. You can download a copy of this guide for your perusal.

*While the Linotype company (under various names) introduced casting type as a slug, its competitor Intertype introduced a compatible and some say superior line of equipment in the late 1910s. Slugs may come from either Linotype or Intertype equipment.

The museum and time capsule s a 11×7×5 inch (28×18×13 cm) solid-wood box with three drawers, one of which serves as a sled to hold the book in its slipcase. It was designed and manufactured by Anna Peterson. The case’s components were cut using a combination of traditional hand tools, modern woodworking equipment, and laser cutters. The two drawers feature cast iron handles reminiscent of those used on type cabinets.

A final perfected copy of the museum

The wooden container and the items within rely on archival-grade materials and joining to ensure it fulfills its long-term goal of being a tiny time capsule. Every box contains a secret compartment.

The Book: Six Centuries of Type & Printing

Hardcover, foil-stamped, bound in Germany

This project includes a book I wrote that traces and explains the development of the craft and technology behind printing from Gutenberg’s invention and modification of several key elements that allowed him to produce his Bible and other work, through the shift from craft-scale presses into the Industrial Age, and then into the development of photographic techniques used in printing and type, offset lithography, and finally the shift to digital.

The book, Six Centuries of Type & Printing, serves as a print companion for the museum, providing context for all the components found in each museum—when they were developed and to what purpose—along with illustrations.

The book is itself an example drawn from history. It was composed in hot-metal Monotype Bembo (in North Yorkshire, England), illustrations etched onto zinc plates and printed by letterpress (in London), and bound in Germany. (You can see more photos of the book in this album.)

The book is a hardcover with gold-colored foil stamping on the cover and spine. It is 8 inches tall by 5 inches wide and 64 pages long. The book has its own slipcase, and for museum purchasers, the slipcase fits into a sled-like drawer at the top of the case.

While it’s a counterpart to the museum, it also stands on its own and may be ordered separately. It ships immediately.

Why Make a Museum?

A Monotype matrix for casting a display size of Albertus at the Type Archive (London)

From 2017 to 2019, I visited five museums of type and printing history in Oregon, Wisconsin, and London: the C.C. Stern Type Foundry, the Hamilton Wood Type & Printing Museum, the Platen Press Museum, the St Bride Foundation’s Printing Library, and the Type Archive. (I even wrote a book about the London ones). I was overwhelmed by the incredible amount of material preserved from the past, much of which had been in danger of simply being thrown out or melted down at several points before the museum acquired it or came into being around it.

I was also taken aback by the financial insecurity of most of these and of other museums and archives of printing history. While some institutions are a point of national pride (like the Plantin-Moretus Museum in Belgium) or privately managed by foundations endowed by families (such as Tipoteca in Italy), many operate on a shoestring budget and have come perilously close to shutting down or having their collections permanently shifted to warehouses, which would make them nearly inaccessible for teaching and research. (This is particularly acute as 2020 progressed, with so many of them unable to open to visitors and run paid educational programs that fund operations.)

During the same period, I took a deep dive into time capsules, looking at the world’s largest time capsule outside of Atlanta (and its problematic roots), the Long Now Foundation’s Rosetta Project, and efforts to preserve history past our lifetimes with the context required to understand it. One of the notions I learned from the Long Now was LOCKSS: “lots of copies keeps stuff safe.”

Pantograph cutting wood type at the Hamilton Wood Type & Printing Museum (Wisconsin)

I wanted to give everyone a chance to own their own tiny museum that teaches and shows the full span of printing history. Every person or institution who purchased a museum also sent it hurtling forward in time as another insurance policy that printing’s past—and all the understanding of how it worked—won’t be forgotten.

My background is a mix of graphic design and journalism. I received a degree in art at Yale, studying graphic design, where I worked with older designers who had spent their lives in letterpress, while I also mastered newly emerging digital tools. I’ve mixed design and writing across my career, in which I’ve mostly worked as a journalist. In recent years, I’ve written for the Atlantic, the Economist, Fortune, Smithsonian, Fast Company, Wired, Increment, and many others.

In 2017, I was the inaugural Designer in Residence in the letterpress program at the School of Visual Concepts, during which time I designed and letterpress printed a book of my researched and reported articles on type, printing, language, and culture. In early 2018, I published London Kerning, the book mentioned above about London’s past and present type culture and archives.

Collaborators and Sources

The museum cabinet. Anna Peterson, a maker of fine wooden spoons, to design, consult, and build the museum boxes. Anna is a writer and editor, doula and quilter, letterpress printer and experienced woodworker, and veteran of Glowforge, a 2D laser-cutter manufacturer. Her fine work shines through every join and bit of polish in the museum cases.

Phil Abel at work at his printing shop (London)

The book’s setting and printing. I met Phil Abel of Hand & Eye Letterpress when I was researching London Kerning in late 2017. Phil is a veteran letterpress printer, and designs and prints fine-art books and projects for art and commerce. His firm, located in London's East End, printed the book and contracted out the platemaking for the images as well as the Monotype hot-metal typesetting, which was handled by Effra Press in North Yorkshire.

Commissioned letterpress print. The museum includes a commissioned work by artist, printer, and designer Stephanie Carpenter, the program officer of the Hamilton Wood Type & Printing Museum. Stephanie’s extensive experience with the museum’s collection married with her fresh, often experimental approach in her work marries old and new.

Wood type. Wood type was purchased, contracted for, and made to order. The museum contains one piece of historic wood type, with a vintage piece dating somewhere between several decades and more than a century ago; one piece of modern laser cut wood type by Scott Moore of Moore Wood Type; and one piece of wood type made using historic tools at the Hamilton Wood Type & Printing Museum.

Linotype and type sorts. I’ve worked with a few different folks casting slugs of type in the Linotype style, and acquired individually cast type from multiple places, historic and modern, including the Bixler Press & Foundry.

Modern letterpress modular element. P22 Analog and the Starshaped Press developed a set of modular printing blocks inspired by modular projects that date back nearly a century. P22 Blox are created through die-injection molding out of plastic.

General items. I sourced from all over, including with the help of people who source and conserve letterpress material for current printers and industrial memory. Special thanks to Larry Lionetti, who regularly places letterpress items for sale on eBay.

Copyright ©2019–2022 Aperiodical LLC. Contact Glenn Fleishman with any questions.